How the car left the factory

This car is a GT. Mine was all blue colour, but without the bonnet vent, front spoiler driving lights and bumper over riders.

The car was built in December of 1969 in Brisbane. It emerged from the factory a metallic blue colour, with brown interior trim (called “saddle”). The engine was a 225 cubic inch in-line six cylinder, with a column change automatic transmission.

In between

The car no doubt went through a few transforations over the intervening years between 1969 and about 1985. In 1985 it was given a make-over to resemble how I bought it.

When purchased

This was my first XY. Bought from a person who guaranteed a “bare metal respray with all the rust removed”, it was almost unsalvageable 5 years later due to rust.

The “new” car was bought from Melbourne in November 2000. It was to replace the other XY that I had that had an extremely rusty body. Rather than restore it (I was quoted $10 000 for the rust repairs alone), I decided to buy another car.

The photos show the old and the new. The old XY was sold locally. I got 20 phone calls and 9 people had a look at the car. I had it for sale for a bargain, as I needed to shift it quickly. Most people wanted to haggle. The guy that bought it had a quick look and gave me a deposit, to return with cash 15 minutes later and drive it away. I’ve not seen it, or heard about it since.

The XW had been a show car some years ago and came with a 302 Windsor engine, Wieand Accelerator intake, extractors, single exhaust and custom interior. The checkerboard graphics on the side of the car dated it to the 80s a little bit.

Front and rear inertia reel seat belts

The seat belts in the car were originally lap sash belts. A previous owner changed both front and rear to inertia reel belts, which are much safer and more convenient.

Re-trimmed XF front bucket seats and original XY rear seat

The interior of the car is trimmed in a blue and black theme. I have kept to this with any new things added, including a blue and black Autotechnica steering wheel.

All metal parts in the car have been painted cyan blue, including the interior metal of the doors, the GT steering column and the dashboard.

Tricked C10 automatic transmission

The heavy-duty C10 was built at the Livonia plant beginning in 1966. Later versions of the C10 were built at the Sharonville Plant until the model was discontinued in 1996. The C10 design was a larger and improved version of the C4. Also, there were many specialty versions of the C10 built for heavy duty factory tugs, airport transporters and even a model for ice rink Zambonis.

My C10 has been shift-kitted for faster, more responsive shifts.

ZG fuel filler

Originally the fuel filler is a cap on the outside of the body. My car had a filler from ZG Fairlane welded in, hiding the cap behind a door. This is a nice custom touch.

Centreline Convo Pro wheels

Tyres:

|

|

Front 185. |

|

|

Rear 255. |

The car has Centerline Convo Pro wheels, a popular choice up until fairly recently. These wheels are used by drag racers because of their light weight and strength. However, many people have moved away from this style.

Set up in the “Pro Street” style, it suits the era of this car. Whilst I’m often tempted to go with a better handling set up with 18 inch or larger rims, the style of the car is one I’m not in any hurry to change.

9 inch limited slip diff

In automotive applications, a limited slip differential (LSD) is a modified or derived type of differential gear arrangement that allows for some difference in rotational velocity of the output shafts, but does not allow the difference in speed to increase beyond a preset amount. In an automobile, such limited slip differentials are sometimes used in place of a standard differential, where they convey certain dynamic advantages, at the expense of greater complexity.

The main advantage of a limited slip differential is found by considering the case of a standard (or "open") differential where one wheel has no contact with the ground at all. In such a case, the contacting wheel will remain stationary, and the non-contacting wheel will rotate freely– the torque transmitted will be equal at both wheels, but will not exceed the threshold of torque needed to move the vehicle, thus the vehicle will remain stationary. In everyday use on typical roads, such a situation is very unlikely, and so a normal differential suffices. For more demanding use however, such as driving off-road, or for high performance vehicles, such a state of affairs is undesirable, and the LSD can be employed to deal with it. By limiting the velocity difference between a pair of driven wheels, useful torque can be transmitted as long as there is some friction available on at least one of the wheels.

The diff is a limited slip Ford 9 inch. Although it is not infallible, the 9 inch Ford rear assembly is popular because of its versatility, combining strength and light weight with the added benefit of a removable third member for ease of set-up and maintenance.

The diff has 3.56 gears, a good compromise for the street. Any higher (e.g. 4.11) and whilst good for acceleration, it makes the motor work too hard on the highway, using far more fuel.

3 core radiator

The radiator is a 3 core unit, allowing for more efficient cooling.

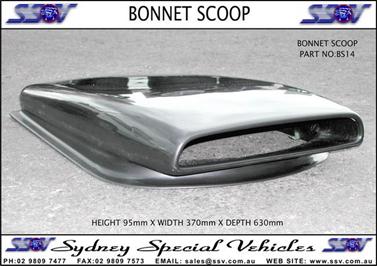

Hornet bonnet scoop

Not wanting to go down the shaker path, the bonnet scoop provided an alternative. It allows cold air into the engine compartment and theoretically improves performance.

Mainly, I like the way it looks.

Custom boot

The boot area has been painted black and carpeted. The tool box and trolley jack have brackets holding them in place. The latch striker and tool box and painted the same colour as the metal parts of the interior. Where the light used to be is a little twin fluorescent light unit and I've included a fire extinguisher.

Why change?

I drove it for 5 years, but regretted not getting an XY, for that was the shape that I preferred. I also started hankering for a little more horsepower. So, rather than be upset, I did something about it. As some rust was coming through, it was time to make some changes.

Change to XY front and paint in XY GT scheme

Most of the paint is XY GT. The car was a Dulux colour called Stark White and this was resprayed in the XY GT colour Polar White.

However, I opted not to paint around the windows in black. This car is not an exact replica, a theme I have continued to follow. For example, I also kept the XW tail lights, as I prefer them. I have not given the back of the car the GT treatment, again to stay away from the exact replica idea.

The stripes along the side were purchased from GT Restorations and could not be applied for a week after the car was painted. This allows the paint to harden, so if the stripes ever come off, the paint doesn’t come with them.

The panel beater who worked on the car had to peel all of the little squares off one by one by heating them so that the glue would lose adhesion. At the end of the process, he swore at me for the burns and said that he saw little squares in his sleep.

The XY parts (grille, driving lights, badges, over riders, front spoiler etc.) were purchased from GT Restorations and from eBay. The aluminium rear wing I had bought at a garage sale in 1996 and it was repainted and put on the car.

351 Cleveland engine

The block is what is referred to as a black motor. It was originally built to do serve in an XE Falcon drag car that ran in bracket racing. So, it’s built to be strong and reliable, rather than as a fire breather.

The engine has been bored and stroked to a 383 cubic inch capacity. It now has blue 9mm ignition leads and a K&N air filter – the old velocity stack is great at high revs (i.e. drag racing) but actually costs 30 horsepower…

351 Cleveland Overview

Before the 351C, there was the 351W which was a 351ci capacity version of the original Windsor engine family - so-called because that is where the original engine factory was, Windsor, Ontario - which started life as a 221ci in 1962, but grew to encompass the famous 289 and 302ci versions through the sixties.

In these small capacity displacements, the 289/302 was a great little engine - and it went on to become even greater in the eighties and nineties - but as car size increased in the U.S. Ford decided that they needed larger capacity from the small block to generate more torque to move the heavier cars. Hence they developed the 351W, but even from its inception, Ford appreciated that while the 351W gave the capacity required, it was a marginal engine from the point of view of developing more and more horsepower as the performance wars of the late sixties escalated. So Ford designed the 351C.

The 351C was designed from the top down with the major amount of effort put into designing the best and most efficient cylinder heads that they could to allow the engine to breathe, and so to rev.

The 351C has a canted valve cylinder head, with splayed valves set at slight angles to one another, unlike the 351W which has parallel valve stems. This canted valve arrangement makes the 351C cylinder heads bigger - wider - than those of the 351W, and as a result it has wider rocker covers. As an aid to identification, the 351W exhaust manifold to cylinder head surface is almost vertical as viewed from the ends of the engine, whereas the 351C has an exhaust manifold to cylinder head surface which sits at 45 degrees and is as near parallel to the side of the block. This can be difficult to see if an engine is in place.

So, the other easy means of 351W to 351C differentiation is to know that the 351C has a dry inlet manifold wherein cooling water does not pass from head to head through a passage in the manifold, but instead passes across the engine in a cast extension to the front of the block. This extension also provides a ‘recess’ for the timing chain and contains the thermostat housing. Simply put, the top radiator hose for a 351C goes vertically into the thermostat on top of this extension, and the 351W top radiator hose goes in horizontally to its thermostat as fitted to the front of the inlet manifold.

There are many different versions of the 351C. Clevelands were designed for the Americans, before moving on to the Australians. Ford U.S. came up with two basic versions of their 351C, the 2V and the 4V. The 2V stands for, as it does most usually, 2 venturis, and describes a two barreled carburetor. American 2V 351Clevelands came equipped with two barreled carbs and as such the engine was designed to be the common version of the engine fitted to non performance cars. To this end, Ford U.S. designed a set of heads for the 2V that had smaller inlet and exhaust ports to promote better low down torque. These small port 2V heads required their own inlet and exhaust manifolds to mate up with the heads and they also had smaller valves. Initial rating of the 2V engine was 250hp.

The first 351C engines to appear in an Australian Ford were those fitted to the XW GT Phase 1.5s built in February, 1970. The U.S. 351C was announced for the 1970 model year and introduced in September, 1969, so it took less than six months for the Cleveland to appear in Australia. The Phase 1.5 - one and a half - was to all intents and purposes an XW GTHO with all the running gear from the 351 Windsor powered Phase1 but with an imported 351C 4V engines fitted. They were cars to tide the market over until the full production Cleveland powered XW GTs were released in April, 1970. The regular production XWGT, powered by the 351C, then ran out the XW model to October, 1970. Later, introduced in June, 1970, was the XW GTHO Phase2 fitted with the U.S. imported 351C engine which had a solid lifter camshaft, and a 750cfm Holley carburetor. You can see that the 351C was regarded first and foremost as its flagship engine.

With the October, 1970 introduction of the XY Falcon and ZD Fairmont range of cars, the Cleveland progressed beyond its performance image and 250hp, two barrel carburetor, 2V versions were offered as the top option on both models. The 300hp, four barreled, 4V version of the engine was only offered on the XY GT and GTHO. Both these engines were still imported, but Ford Australia was keen to build its own and had tooled up to provide locally manufactured 351C and 302C engines. Why tool for a 302C engine when they had been using the 302W? Well, it provided economies of scale, being able to use all of the ancillary parts from one engine on another, and all for the sake of a different crank and rods.

And so the March, 1972 introduction of the Australian designed XA Falcon range also saw the debut of Australian built 351C and 302C in two barrel carbed, 2V form. There have been some reports that 302C’s were fitted to Brisbane built, December, 1971 XY Falcons. Brisbane cars have the letter ‘H’ as the second letter of their VIN. For the moment, the four barrel, 4V engines were imported, but by the early/middle of 1973 Ford Australia had developed their own four barrel fed 351C but used their own 2V style heads on the engine.

This is where the 2V and 4V descriptive terms become somewhat entwined. The distinct separation that applied in the U.S. between 2V and 4V ensured that a 2V Cleveland had a two barrel carb and inlet manifold, small inlet and exhaust ports and an enlarged chamber volume, while the 4V Cleveland had a four barrel carb, large inlet and exhaust ports and reduced size chamber volume which created a higher compression ratio. Now the Australians introduced a 2V head that took either a two or a four barrel carb inlet manifold, and had a large, but not as large as the U.S. 2V, open chamber size, plus, for further confusion, they introduced a 302C engine that had 2V heads which had a two barrel carb but a chamber volume smaller than anything the U.S. had offered, even on their highest performance Clevelands.

While the home grown four barrel, 2V 351C was introduced on automatic XA GTs towards the end of its life, the last of the imported, high compression, big port, 4V U.S. engines lasted only through to the first few months of XB GT production, again mostly, but not exclusively, in manual transmission cars, and by January, 1974, they were gone and all 351C engines that followed were Australian made.

The 351C ran through till the middle of the XE Falcon’s life before, to howls of protest, Ford killed off their V8 in 1982. In its later life it suffered compression ratio cuts, emissions equipment additions and a swap to Carter carbs to keep it clean and healthy.

My Car is a “Square” block

This is a D Block – note the “D” shape near where the fuel line loops

The terms ‘D’ block and ‘square’ block apply to differences in the casting of the engine block. The ‘D’ block is the earlier casting, in fact the initial casting of the 351C block and the ‘square’ block is the later one. How much later is open to conjecture. ‘Square’ blocks would appear to have been available in the U.S. in 1971, and there is some evidence to show that the ‘square’ block appeared in automatic XY 351C 2V’s as early as May, 1971, and in manual XY 351C 2V’s in December, 1971. It does appear that XY 351C 4V engines continued with ‘D’ blocks. What can be said though is that no XW or XY GT came with a square block, and that all Australian built engines are patterned after the ‘square’ blocks.

This is a Square Block – note the square in place of the D shape

Double row timing chain

Double row timing chains have more inherent strength, just by being physically bigger: stress would be distributed across a greater surface area. This makes them more reliable in higher horsepower engines.

High volume oil pump

Given the characteristics of the engine, the stock oil pump was having trouble. A high volume pump was needed to be safe.

Hi Energy sump

The SUPER PAN is the latest development of High Energy's Classic Design.

It features a full length multi louvre windage tray to stop the crank from blowing oil out of the deep section of the oil pan and to help scavenge the oil away from the crank and release horsepower.

The crank scraper helps to prevent oil being blown up the sides of the pan.

750 cfm vacuum secondary Holley carburettor

The 600 cfm was a borderline choice – the motor was a little under-carbed. A mate had spent a fortune on a carb that turned out to be too large for his needs in an XD ESP Fairmont Ghia. A metering block had been placed in the non-adjustable side of the carb to make it adjustable on both sides, so it could be properly tuned.

Holley electric fuel pump with upgraded fuel lines

The mechanical fuel pump couldn’t keep up with the new motor, so I went with one of the new Holley electric pumps These have an internal regulator and are a bit quieter that a Holley Red or Holley Blue.

They feature:

|

|

Gerotor Design For Smooth Operation And Durability |

|

|

Flows 125 GPH Free Flow. |

|

|

Flows 110 GPH at 7 PSI. |

|

|

Powers Engines from Stock All the Way Up to 700 Horsepower. |

|

|

Black Mil-Spec Nickel Teflon Hard Anodized Billet Base. |

|

|

Show Quality Chrome 12v Motor. |

|

|

Less Noise than Traditional Vane Pumps (Much quieter than a Holley Blue or Red Pump). |

Redline Torker single-plane manifold

Selected by the person who fitted the motor, this manifold increase flow rate into the motor.

Whilst this manifold is working out OK, a dual plane type won’t increase power, but will make it available earlier. I’ll change to one when practicable.

Hydraulic cam

Hydraulic-roller cams (top) are generally built on harder camshaft cores to withstand the higher unit loading pressure of a hardened roller follower. Flat-tappet cams (bottom) are generally hardened cast iron. This is the main reason why roller cams are more expensive.

These cams offer significant advantages for additional lift and more power when properly combined with the rest of the engine combination. That's what has everyone so excited. But there are some practical pitfalls. The big limitations are cost and all the other details that must be accomplished before you can take advantage of everything that hydraulic-roller cams have to offer.

A grind to suit the motor, the cam is quite lumpy. On idle, the car rocks slightly from side to side.

B&M Quicksilver shifter

The B&M QuickSilver automatic shifters have cable-operated ratchet action for dependability, and a chrome plated stick and cover for good looks. These QuickSilver shifters include an NHRA/IHRA-approved reverse lockout, a neutral safety switch, a backup light switch, a lighted gear indicator, and they will work with reverse pattern valve bodies.

One piece black carpet

The old carpet was getting worn and I had a one piece carpet under the house from years ago. I unfolded it and it was still excellent, so in it went. The old carpet was a number of sections cobbled together, so the new carpet gave the car a real lift.

New head liner

Sourced from eBay, the lining appeared grey and I was a bit worried. Once in the car, it looked blue. Much better.

Viscous radiator fan clutch

This clutch is coupled to the radiator fan. The principle is that the fan doesn’t spin until the engine gets warmer, meaning that it gets up to operating temperature faster.

XA front brakes

The brakes needed overhauling and the XA system fits. Interestingly, it’s about half the price of XY units, event hough it’s a better set up. The callipers are now XD units, as they have a 40% larger pad area.

(The picture is of a brake upgrade, not the brakes I put on my car, but you get the idea.)

Pioneer sound system

|

|

Pioneer AM/FM CD head unit |

|

|

Pioneer 5 channel amp (Boot mounted) |

|

|

Pioneer IMPP sub-woofer and custom enclosure (boot mounted) |

Now

Once I had the car approaching what I wanted it was tuned on the dyno. After 9 runs it was tuned within an inch of its life and was making 320 horsepower at the rear wheels. To make more power, it takes much more money. Doubling horsepower doesn’t mean doubling cash – more like three of four times, as you have to start strengthening other areas of the car – driveline, cooling, structure, internal engine components etc. The horsepower roundabout is one ride I’m not staying on for long.

The result is a package that recognises an icon of the Australian motoring industry whilst not being a slave to it. With a 12.5 second quarter mile time under its belt it’s no slouch, but it doesn’t over heat in traffic and starts first time. It’s fuel consumption around town is fairly heavy, but I drove it to Bundaberg recently, a round trip of 220 km. On the trip it used 23 litres of fuel, which is very reasonable. Whilst it’s no show car, it’s still an attractive and interesting car.